Both our plants are Spread over 1,00,000 sq.ft, with latest machineries and technologies coupled with a dedicated work force. The company provides stipulated working atmosphere with all amenities needed for good working conditions. Plans are underway to double the existing capacity within next few years and expanding the tool room.

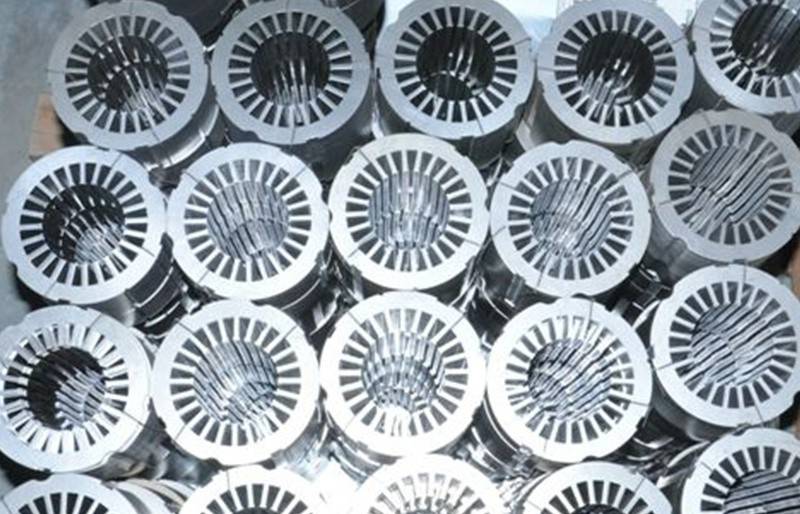

The entire process of stamping at the high speed presses is performed with progressive tools manufactured in-house. The shorter lead-time is made possible by integrating what are individual processes in the low speed presses, into a single comprehensive process. Since the processes are not split, a streamlined flow is effected, leading to quality output in a short span of time.

One of the distinct features that enable RML to consistently deliver quality solutions is its onsite tool room, which facilitates precision designing of the required tooling equipment for stamping and lamination. The tool room is specially equipped with single, double, triple cavity tools, and can undertake complex designs such as

Enabling the state of the art, Our Tool Room is equipped with high precision machines like wire cut, grinding, jig boring and jig grinding, etc.

The stamping and lamination facilities are segregated into two separate functioning segments at the production facility.

The company sources principal of steel from quality conscious suppliers both in India and abroad.

For its die-casting requirements, RML sources 99.9% pure electrical grade Aluminum. RML has also flexibility to produce smaller quantity with their gap presses and notching machine. RML can supply components in cleated, auto-stacked and in loose conditions.

RML believes in the CORE strength of values to understand, innovate and deliver.